processanalyser

Description

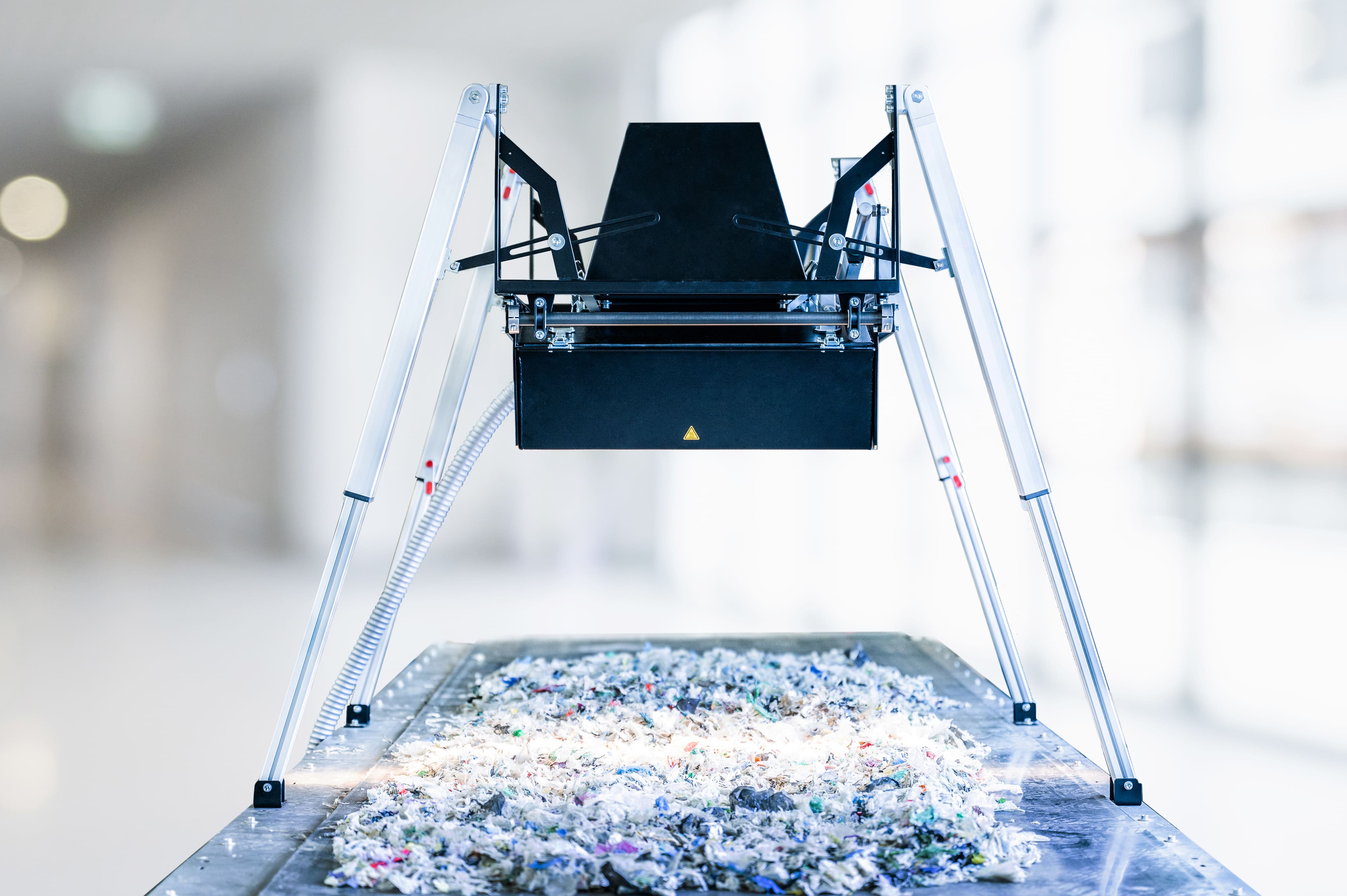

The processanalyser is a semi-mobile, AI-based multi-sensor analysis system for fast and non-destructive quality control and material analysis of a wide range of material flows. The area of application includes both shredded materials (flakes) and uncrushed objects.

The product consists of the detection unit, which is mounted on the conveyor belt to be monitored, and the control unit, in which the central evaluation unit is integrated. All external media are connected to the central control unit.

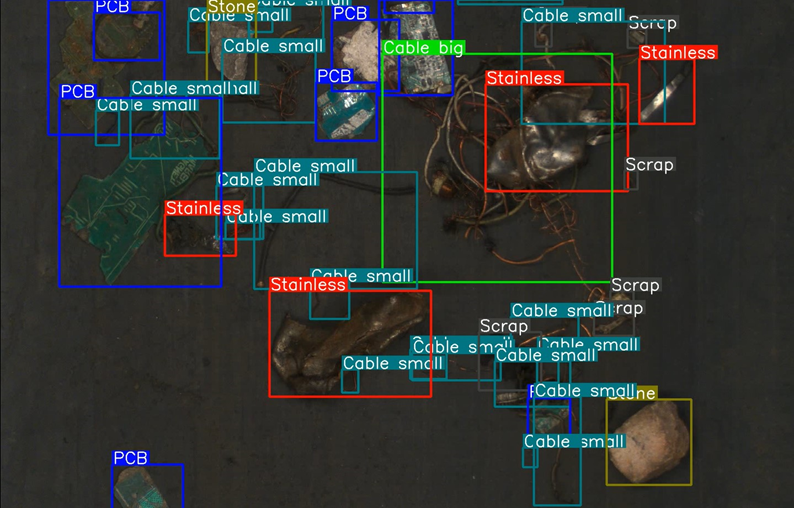

State-of-the-art HSI technology enables a very broad spectrum of detectable materials. In conjunction with the full integration of a high-resolution colour camera, this configuration enables, for example, the linking of colour image data with NIR material data in a new dimension. The evaluation of all the data captured by the process analyser's detection module comes together in the control system and is analysed here using AI-based algorithms.

This proven method ensures a high level of reproducibility of the data generated and is characterised by a high degree of flexibility, allowing new objects to be easily taught in and integrated into the existing evaluation algorithms. This teach-in can be carried out via remote maintenance.

As an inline scanning tool, the process analyser can be installed directly on the existing conveyor belt at any point. As the device is not dependent on a monolayer, it can also measure the quality of non-separated material flows. Belt speeds of up to 4 m/s can be covered.

Typical Applications

Chemical Recycling

The device is suitable for the final inspection and determination of the material composition before it enters the chemical process. With the help of live data, the process can be better adjusted and controlled for possible fluctuations.

RDF Power Plant

Determining calorific values and water contents are the key issues here. Here too, the live data helps to control the process more precisely.

Sorting Plant For Lightweight Packaging

As a semi-mobile analyser, the processanalyser can be mounted alternately above various conveyor belts and can determine the end product quality before it is discharged into the bunker, for example, or quantify losses in the residual materials. Furthermore, preparation steps within the process can be checked (e.g.: film content in 3D, material groups in internal material recycling).

Within the individual fractions, the AI enables the determination of food and non-food proportions, for example.

Scrap

- Ferrous products can be analysed for the presence of impurities such as meatballs

- Non-ferrous products can be analysed for the presence of cables, circuit boards and residual materials

Waste Wood

- Analysis of different qualities such as A-wood and B-wood or various impurities

Device features

- AI-based analysis according to

- Material type

- Object colour

- Surface structure / volume flow

- Simultaneous assignment of detected objects according to colour and material

- Inline measurement

- Semi-mobile design

- Automatic calibration function

- Automatic protocol output

- Automatic archiving of measurement results

- Automatic determination of belt speed

Technical data

Sensor fusion: NIR sensor / high-resolution colour camera / 3D sensor / metal sensor (optional)

Detection dimensions: 1,250 mm height, 650 mm width, 680 mm depth

Switch cabinet dimensions on wheels: 1,300 mm height, 1,000 mm width, 400 mm depth

Weight: approx. 50 kg

Connected load: 1,9 kW (230 VAC, 16A)

Grain sizes: 6 - 350 mm

Suitable conveyor belt widths: 600 – 2,000 mm

Maximum belt speed: 4.0 m/s